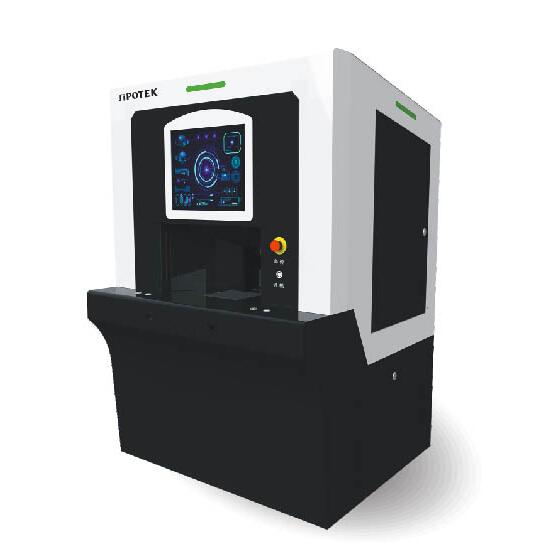

Sipotek is a professional china automated optical inspection machine manufacturers located in shenzhen city,major products including visual inspection machine and automated optical inspection (AOI) machine.

What products can be inspected by Sipotek vision inspection equipment?

It depends on what kind of inspection you are looking for. Take inspecting dimension and appearance for example.

For dimension inspection, please provide us samples contain good quality at lest in 2 pieces, and the bad quality as much as possible. Moreover, you need to provide a paper that marked with the size/ dimension you want to inspect.

For appearance inspection, please provide us samples that you had human-inspected already, and categorize the samples with notes. Our engineer department will test by the software system and give you the analyse solution, then you can make the decision.

We are manufacture specialized in precision measuring equipment. We won’t keep arbitrarily promise to our customer with unreliable things.

Sipotek has been focusing on visual equipment for 16 years. We has many successful cases in various fields. Our technology, service and quality have been verified and recognized by hundreds of companies. Good impression is built by time accumulation and customer recognition. Sipotek is strict with self-discipline, profession and dedicated, focusing on quality inspection.

We welcome your inquiry and visiting our company.

For more about automated optical inspection manufacturers,you can pay a visit to https://www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net