Sipotek is a professional china automated optical inspection machine manufacturers located in shenzhen city,major products including visual inspection machine and automated optical inspection (AOI) machine.

Today we will talking about wide range of automated visual inspection systems working by high resolution and high speed industrial machine vision camera system.

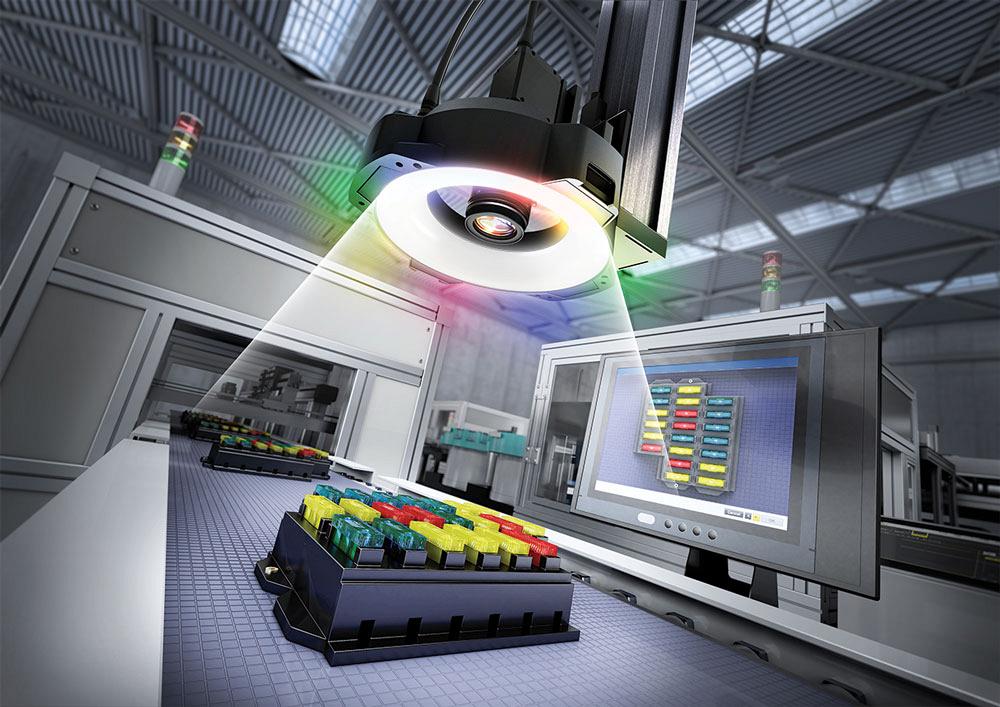

A Visual inspection machine use image and camera processing software to inspect and examine the quality of the parts and the processes used. It plays a vital role in arriving at the maximum efficiency in manufacturing and production, as well as in reducing the cost of processes.

The search for state-of-the-art automatic visual inspection machine for industrial purposes is fast becoming essential in many areas to improve data acquisition and quality control as well as for data analysis. Suck kind of systems are an ideal tool to possess to help you gain control and assess industrial and vision systems in the factory. The advanced systems have widespread use in the industrial and scientific community for the maintenance of facilities or the inspection of equipment and facilities.

These exclusive systems all make use all the key technologies to create highly creative vision systems. The highly specialized vision systems cover many major activities such as video detection and image processing software. Smart and digital cameras are also a major part of these advanced visual inspection machines, as well as real-time processing units, application software, and lighting units.

This state-of-the-art equipment is capable of performing parts inspections, label inspection, web inspection, bottle inspection, quality control packaging, 3D reconstruction and so much more. A handful of these systems are also useful as traffic monitoring systems thanks to their intelligent multifunction technology.

The high-tech operation of this system is as a result of the excellent combination of many enhanced and advanced vision tools, as well as the acquisition and processing of high-speed images that they capture. It is also very easy to set up and distribute these visual inspection systems where you want them. Also with these systems, comes an easy-to-follow software that even an inexperienced user can use to configure the system. It is possible to configure these systems even by non-programmers or without knowledge of the spreadsheet.

Most reputable and reliable control systems are readily available at very economical prices and there is a vast range of these control systems on the market. You can choose the one that meets your budget and performance requirements.

Now, some of the unique features of most inspection systems are perfect data integration, plug-and-go configuration, automatic detection, faster image updates, tiled views of nine vision systems, visualizations of filtered images, display of complete and colored images and much more.

You can locate some of the very formidable visual inspection machine with unrivaled capacity to locate and inspect by conducting an online search. These autonomous control systems are the ideal choice for quick and easy installation in scientific and industrial fields.

When you are looking for automotive equipment and tools, it is best to check on the internet to locate the best measuring and gauging materials. Items such as feeler gauges, manometers, die cutters and visual inspection systems are available from several companies. Make sure to research the company to make sure you get the best custom measuring gages to suit your needs.

To learn how a visual inspection machine can automate the production process, one can visit the website https://www.sipotek.net/ .

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net

Pinterest:https://www.pinterest.com/chinasipotek/

Website: https://www.sipotek.net/industries/

Website: https://www.sipotek.net/machines/