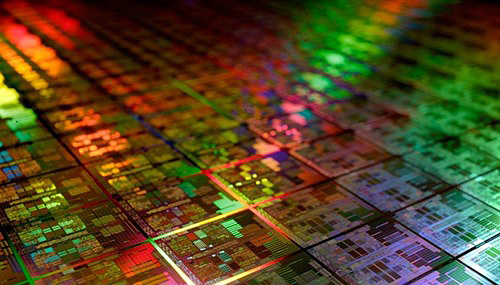

The automated optical inspection machine developed by Sipotek Technology allows visual inspection of products during the manufacturing process to help detect any defects.

With their great experience in the image technologies, Sipotek Technology designs and develops visual inspection machines that can be used for checking defects in products and devices. These machines can allow to conduct inspections at various stages of product development, so that flaws, errors and component missing issues can successfully be avoided. The machines are designed to automate the production process and maintain the quality of the finished products.

According to the company spokesperson, the Sipotek Visual Inspection Machine uses the image comparison technology to match the image of a product with the given template. This makes it possible to detect any flaws in the product and which can be rectified before the final production of the product. The company offers full size precision testing machines that adopts the dynamic data acquisition algorithms and carries out the image analysis to automatically detect any error in the product. The machine features an excellent detection speed and outstanding detection accuracy, and can test glass, steel and various other materials. The machine can also be upgraded to include the 3d visual detection capabilities.

The company particularly boasts of its automated optical inspection machine that is aimed at reducing the human error of inspection. In the traditional production processes, humans are engaged in the inspection process, and which is often prone to errors. On the other hand, the automatic inspection machine uses the superior image vision technology to quickly and successfully detect all types of errors, whether it is related to quality or missing components. The machine can capture high resolution images of a product at a staggering speed of up to 100 frames per second. According to the needs of the manufacturing process, the machine can capture product images and which can be processed automatically to find out any defects or errors in the product. Besides the product inspection, the machine can also carry out certain tasks, such as product identification, barcode reading, character recognition and others.

The spokesperson states that in today’s competitive environment, a company cannot rely on human inspection mechanisms alone. The company’s visual inspection machines make the task of error detection fast and simple and help automate the entire production cycle. A complete inspection of devices negates the chances of a catastrophic failure, while maintaining the quality at the same time. By combining the latest technologies, such as 3d visual and data analysis, the company develops machines that not only inspects products, but also process them. Using industrial cameras and image processing software, these machines can perform a robust image inspection and meet the customer demands.

To learn how a visual inspection machine can automate the production process, one can visit the website https://www.sipotek.net/ .

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net

Website: https://www.sipotek.net

No comments:

Post a Comment