Shenzhen Sipotek Technology Co., Ltd. is a professional automatic visual inspection machine ,automated vision inspection system,industrial machine vision camera,automated optical inspection machine ,optical sorting machine manufacturer from china with low cost and high quality.

What are the advantages and disadvantages of non-destructive testing? Non-destructive testing (NDT) offers a safe and reliable way of inspecting components, that is cost effective and requires little to no disruption to workers or machinery.

It means that plant and factory operations can continue working without any damage to equipment, or any loss of income to the company. This type of testing is used primarily to detect, identify and measure anything that could cause damage to a component such as cracks or corrosion.

Non-destructive testing is a means of testing a component without causing any detriment to it, and it therefore requires the use of a qualified technicians who are expert in their field. Format NDT are able to help with any form of non-destructive testing.

Today we will talking about advantages and disadvantages of non destructive testing with visual inspection machine : process of expulsion up and process of expulsion down.

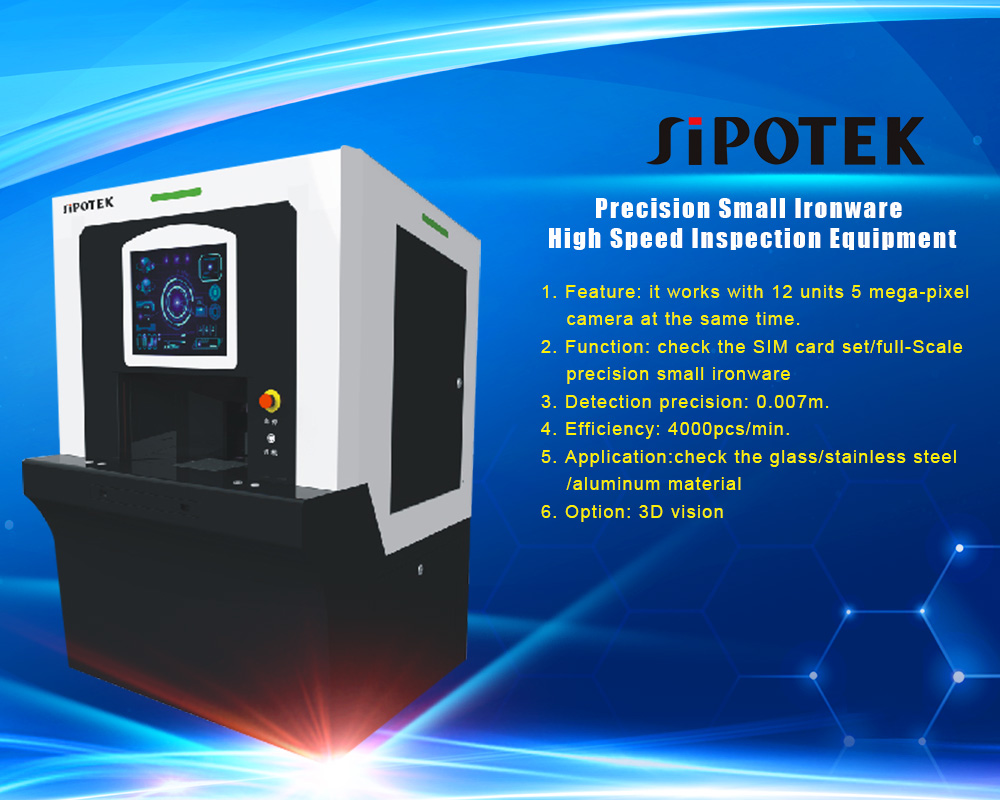

Sipotek Visual Inspection Machine 9

All vision inspection system manufacturers have integrated into a visual inspection machine a final process known as the expulsion, and this is responsible for correctly placing all the objects that are being classified, that is, that takes each one to the place that corresponds.

This allows them to have in an orderly manner the elements that meet the specifications of what is right, and which must be completely discarded. Once all the correct element sets have been determined, the final expulsion will proceed.

To create the ideal visual inspection machine you must

Vision inspection system manufacturers know that when a customer requests the manufacture of a visual inspection machine, it indicates some specific needs regarding their products. They also consider that multiple products are different, so they have to find the right way to process them.

To decide what is the best way to expel all the elements, many vision inspection system manufacturers must decide whether an expulsion will be incorporated downwards or one upwards. And this is decided based on certain criteria that may be presented according to their advantages and disadvantages.

Advantages and disadvantages of expulsion down

The ejection down is the method where the ejector element is at the top of the machine and ejects down the elements indicated by the sensor.

Advantages

One of the main advantages that includes the use of this method is that the receiver of the elements can better catch the rejected material, this due to its position, since it can be completely assured that it will be within the corresponding selection.

The containers remain firm and there is no possibility of overturning it.

Disadvantages

The disadvantages of the ejection down start with the distance from this ejector to the belt that contains the materials, since being so far away sends a current of air that can force other materials to enter the container of the rejected .

It is also possible that the speed with which the other elements are transported causes the correct ones to fall by themselves into another container.

Advantages and disadvantages of expulsion up

When talking about an expulsion upwards, it is determined that the ejector element of the machine is at the bottom of it, and from there changes the course of the elements according to the determination of the classification and the orders of the programs.

Advantage

In this method the ejector is very close to the elements that the band carries, so the process will be much more precise than others, selecting the material properly, without compromising others that are nearby.

If the conveyor belt does not work properly, by inertia the materials will fall into the container of the rejected, without compromising the content of another.

Disadvantages

In some cases of expulsion, it cannot be assured that the material will enter the container completely since it can take a very different direction, so its fall cannot be completely controlled.

The choice of expulsion method is subject to the type of material for review and to the client’s specifications.

For more about visual inspection machine,you can pay a visit to sipotek at https://www.sipotek.net/machines/

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

Sipotek Visual Inspection Machine

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net

Website: https://www.sipotek.net

No comments:

Post a Comment